What We Do

TTC Labs can improve every operation of your refinery or solve your most difficult problems. TTC is the Worlds leading process engineering company that provides the experts for the experts. The TTC engineers solve the most difficult problems and do the most challenging revamps. The results for OpEx are quick improvements in operating margins, robust ongoing operations and low-cost modifications that eliminate later high cost revamps. For CapEx, the expertise is used to be opportunistic in the re-use of existing equipment and exploiting the existing assets. (see Case Studies)

TTC Labs has provided process expertise to most major engineering firms and over 200 refineries. The list continues to grow based on repeat satisfied clients. Our team of over 15 senior process engineers average 35 years experience. (See Our Experts)

What Do We Do Best?

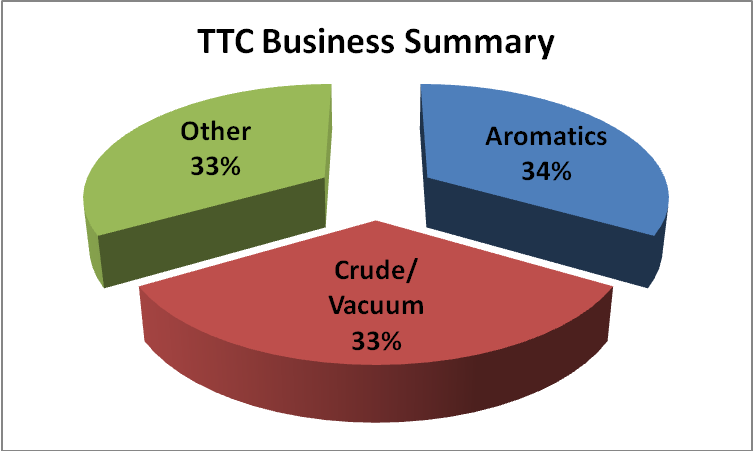

About two-thirds of TTC’s business is in Crude Units and Aromatic Units . TTC has developed patented and proprietary technology that out performs any other process designs in use today.

About two-thirds of TTC’s business is in Crude Units and Aromatic Units . TTC has developed patented and proprietary technology that out performs any other process designs in use today.

Our Crude Unit Technology not only increases your crude units capacity, but it also makes it more profitable and efficient. TTC can increase the volume of your gas oil feed to the cat cracker and eliminate up to 99% of coking in the VCU. This can be done at a lower CapEx than you anticipate. (See Crude Units)

Our Aromatic Unit Technology has no peers when it comes to generating the most profit and reliability from your Aromatic Unit. Our BTX PURE Extraction technology robustly delivers “on spec” products, maximizes your capacity, and reduces your energy cost and carbon footprint. Aromatics are one of the most difficult processes to engineer correctly in your refinery. (See Aromatic Units)

Our Reforming Technology stands TTC out from other engineering companies. Our Reformer Window is a unique program that allows engineers to be able to adjust the internal conditions of a reformer. TTC’s engineers have the most advanced knowledge of all types of reformer hardware and how to optimize the results. (see Reformer Units)

Onsite Services

Our Onsite Services are the specialties that are responsible for the technical part of our business. These services are in constant demand from our clients because they provide the fastest way to raise yields and profits for the least amount of expense. Our process engineers specialize in squeezing the maximum yields from your refinery without major CapEx and offer the best ROI your company can make.

Our Troubleshooting, Optimization and Design Evaluation services are where refineries can make quick returns through process engineering changes without a costly equipment purchase. (See Onsite Services)

Our Training & Service Are Key. TTC provides onsite training to your engineers to make sure they fully understand our design process and how to make them operate at the most efficient levels. We are always just a phone call away to answer any problems that may arise. (See Our Case Studies)

Cat Cracker (FCC) – Coker – Hydrotreaters – Hydrocracker

The TTC engineer team has extensive years of experience in all of these areas that will deliver superior results in a very cost effective manner. Our engineers regularly deliver Optimization, Revamp Designs, Start-ups, Grass Root Designs and Debottlenecking designs for virtually every operation in your refinery. (see Our Experts)

307-200-1789